Acoustic Fabric

Acoustic Fabric has been tested and work well with the track system.

Acoustical Fabric Specs:

ASTM C 423 – Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method; 2000.

Acoustical Absorption: Perform testing in accordance with ASTM C 423, Type A mounting method unless otherwise specified

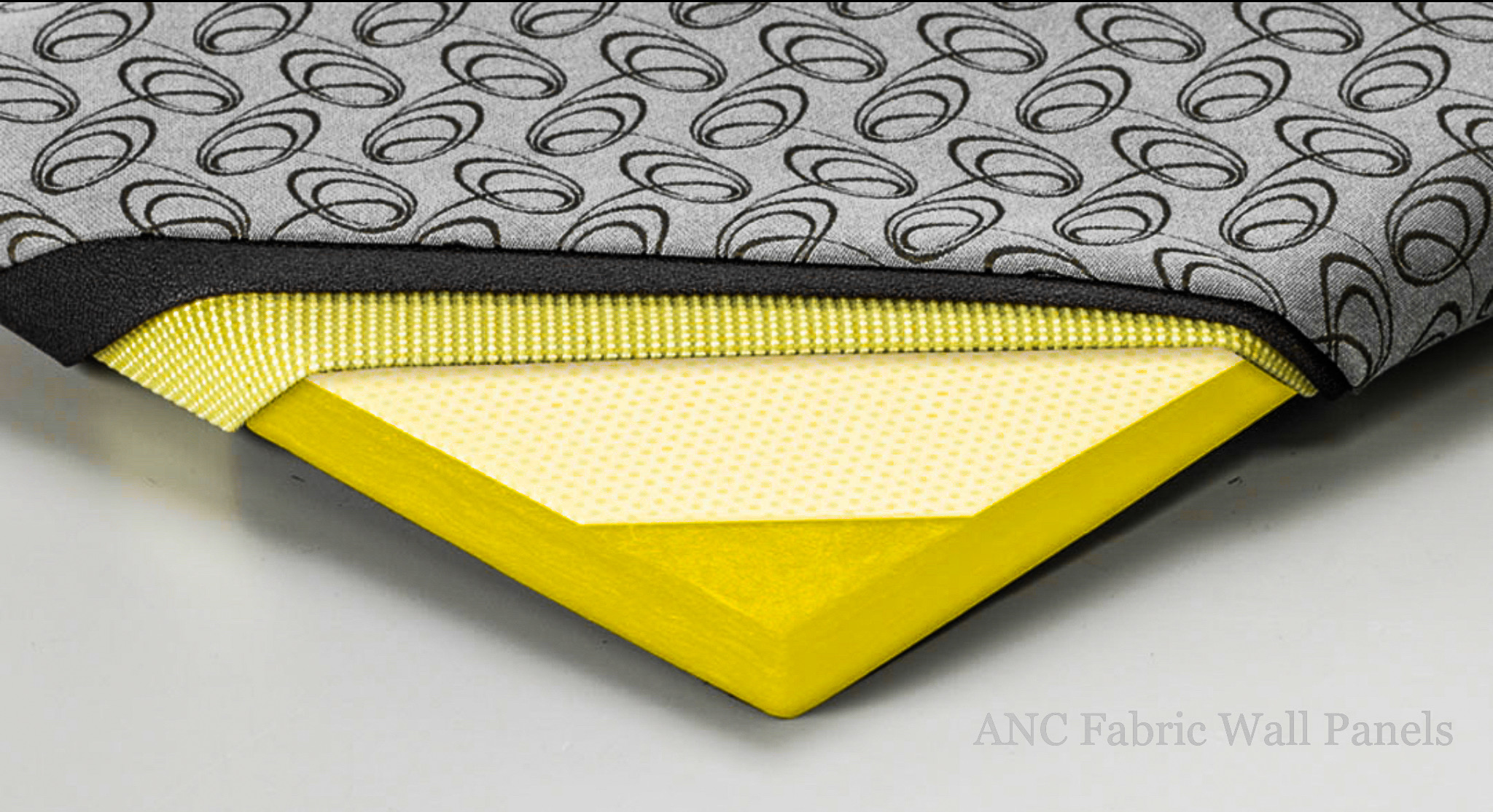

Core Materials:

1. [1”, sound-absorbing 6 pcf fiberglass, NRC = .80]

2. [2”, sound-absorbing 6 pcf fiberglass, NRC = 1.05]

3. [1”, sound-absorbing and tackable multi-density fiberglass with 1/8”, 18 pcf facing sheet, NRC = .80]

4. [2”, sound-absorbing and tackable multi-density fiberglass with 1/8”, 18 pcf facing sheet, NRC = 1.00]

5. [2”, low-frequency sound-absorbing fiberglass core with bass trap facing, NRC = .55]

6. [1”, LEED Certified, 80% recycled core, NRC = .70]

7. [2”, LEED Certified, 80% recycled core, NRC = 1.00]

8. [2”, two dimensional, thermoplastic sound diffusers.]

9. [ “, tackable mineral fiberboard.]

Finish Material:

1. Manufacturer’s standard Guilford 2100 polyester fabric.

ACCESSORIES

Mounting Hardware: Installer shall provide fasteners to securely install track and core materials to the substrate.

Installation Tools: fabric tucking tools are required for the installation of stretch fabric.

Installation:

A. Install stretch fabric wall in accordance with manufacturer’s written instructions where indicated on drawings, scribed to fit adjoining work accurately at borders and at penetrations.

B. Frame Materials: Install track level, plumb, and securely fastened to supporting substrate.

C. Core Materials: Mechanically attach securely to the supporting substrate.

1. Core material to be fit tight and flush with the top edge of the track, free from bumps and protrusions.

a. The use of adhesives is unacceptable.

D. Finish Materials: Fabric shall be removable for ease of replacement.

1. The use of manufacturers’ fabric tucking tools is suggested.

2. Fabric to be stretched taut without wrinkles or sagging.

3. Fabric will be cut from manufacturers’ roll, marked, and shall be installed in matching sequence.

a. Maintain fabric wrap and weave during installation.

b. Maintain fabric patterns throughout the installation.

CLEANING

A. Clip or tuck loose threads and extraneous materials.

B. Clean stretch fabric facing, on completion of the installation, to remove dust and other foreign materials according to manufacturer’s written instructions.

PROTECTION

A. Provide final protection and maintain conditions, in a manner acceptable to manufacturer and Installer, to ensure stretch wall system is without damage or deterioration at time of Substantial Completion.

B. Replace stretch wall system that cannot be cleaned and repaired, in a manner approved by Architect, before the time of Substantial Completion.