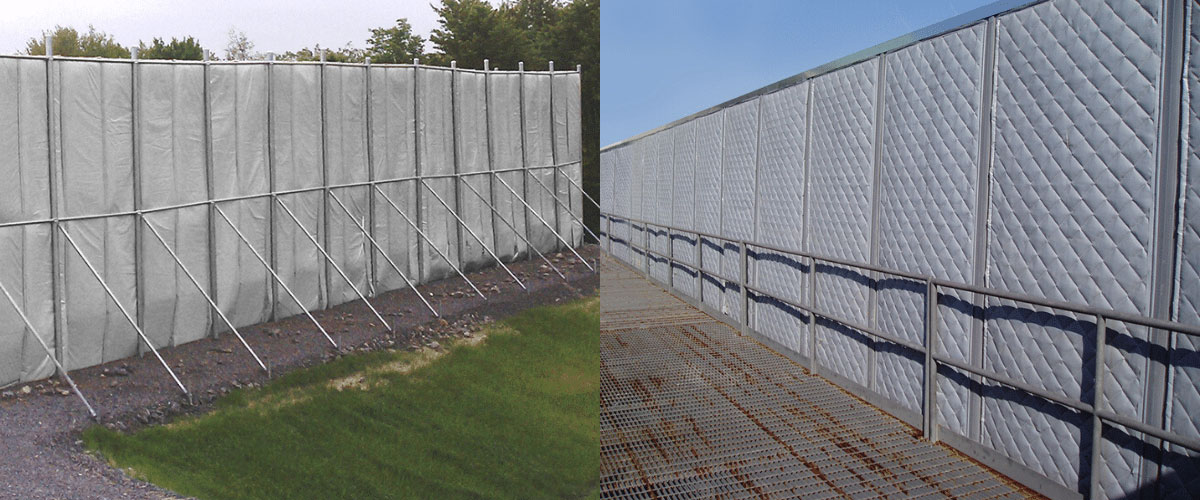

Soundproof Fence Barrier easily installed or removed in less than one hour. Totally NON-mold and UV tolerant, this material is virtually indestructible and does a wonderful job as a sound barrier.

Independent lab tests of the Soundproof Fence Barrier material shows an STC of 28, which represents to the human ear approximately an 85% reduction in sound. However, results will vary, relative to surrounding sound reflective objects, i.e., buildings, and how much of the fence is installed.

The manufacturer suggests you consider your noise source as a bright light bulb on a very dark night. To reduce that light the first step is to put a barrier (Soundproof Fence Barrier ) between it and you, blocking the direct light. Other objects in the area not blocked by the Soundproof Fence Barrier , will of course reflect an amount of reduced light to you. Sound will act in the same manner.

Other features of Soundproof Fence Barrier :

|

Soundproof Fence Barrier :

|

Soundproof Fence Barrier material is extremely strong and engineered to withstand outdoor construction sites, highway environments, and most other outdoor applications. Full exposure to dirt, grease, oil, mold is not a problem for Soundproof Fence Barrier . You can even drive over it without decreasing it’s effectiveness.

Having black anodized brass eyelets every 6 inches on the top edge and some on the bottom, allows easy hanging or attaching of the fence to just about anything. Heavy duty nylon wire ties are supplied with the fence and stainless wire ties are available at additional cost. Multi-level construction projects can easily overlap multiple lengths of Soundproof Fence Barrier attached to scaffolding to achieve many floors of vertical height sound blockage.

Staggered wood shadow box privacy fences (which of course provide no acoustical privacy) can easily incorporate Soundproof Fence Barrier without changing the visual appearance. Simply remove the vertical wood slats on your side of the fence, install the Soundproof Fence Barrier and reinstall the wood vertical slats. This is very easily done and leaves the appearance intact while adding acoustical privacy. A hammer, small crowbar, screw gun and some non rusting screws should be all the tools required.

|

Soundproof Fence Barrier Installation

Soundproof Fence Barrier Installation